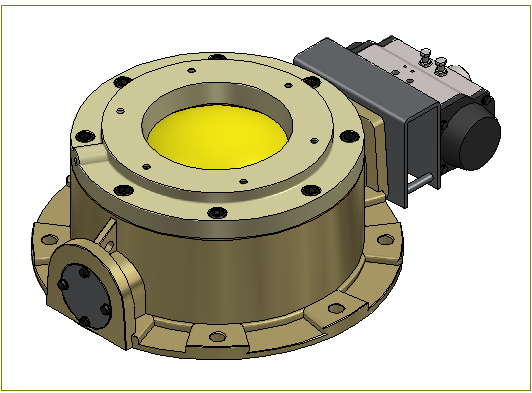

The EMOD Valve is a full-bore, inflatable-seal dome valve designed to overcome the common failures of traditional valves (like butterfly, knife-gate, and ball valves) in abrasive, high-pressure applications. Its unique operating principle provides a bubble-tight seal and long service life in the most challenging industrial environments. Understanding this technology is critical to positioning the EMOD valve as the solution for process-critical applications.

What is Dome Valve?

Dome Valve are not common means of isolating high-pressure equipment. They are pressure tight, Power – operated valve for application in the material inlet, vessel discharge, line change over, discharge from pressure chambers. The valve provides an inflatable sealing arrangements which is designed to open and close by actuating a pneumatic actuator by an external 5/2 solenoid valve and sealing is done by another 3/2 solenoid valve.

This design achieves two things that most other valves cannot:

- Closes on a Static Column: The dome has a powerful "wiping" or "cutting" action. As it rotates to close, its curved profile can push material aside and close securely through a moving or a static column of material. This means the process does not need to be stopped to actuate the valve, preventing jamming and ensuring reliable operation as a true process isolation valve.

- Full, Unobstructed Bore: The valve's sealing mechanism is not friction-based. A pneumatic, inflatable elastomeric seal provides the sealing action after the dome is already in the closed position. This soft seal is completely shielded from the abrasive material flow when the valve is open, dramatically reducing wear.

- Protected Inflatable Seal: The valve's sealing mechanism is not friction-based. A pneumatic, inflatable elastomeric seal provides the sealing action after the dome is already in the closed position. This soft seal is completely shielded from the abrasive material flow when the valve is open, dramatically reducing wear.

Operating Principle & Mechanism

The dome closes below the seal when the inflatable seal is relaxed, allowing a clearance between the seal and dome flap. In the closed position, high pressure gas enters the space between the back of the seal face and the insert ring to cause the seal to expand onto the periphery of dome flap. Material is entrapped by the seal against the dome surface, irrespective of particle or shape. Before opening the valve, the seat is relaxed, and the gap is reestablished before the dome component moves to its open condition. The seal can be accessed by loosening the top plate fasteners detaching the insert ring and spigot plate.

Inflatable flexible seats entrap particles that are normally the cause of seat erosion. Particles are induced to move across valve seats under the influence of pressure differentials on either side of the closing member. Entrapping particles within a flexible face during the period of valve closure prevents particle movement and considerably reduces valve seat wear. Inflatable seats allow automatic wear compensation.

- When the seal is relaxed, the dome component can open resulting in a full bore opening hence allowing material to pass through and fall from the dome valve into the bottom process.

- In the closed position, high-pressure air / gas enters the space between the backside of the seal face and the insert ring. This causes the face of the seal to expand towards the dome surface, irrespective of the particle size and shape. This ensures pressure tight sealing of the dome.

- The above control sequence is made to repeat for the next cycle of operation.

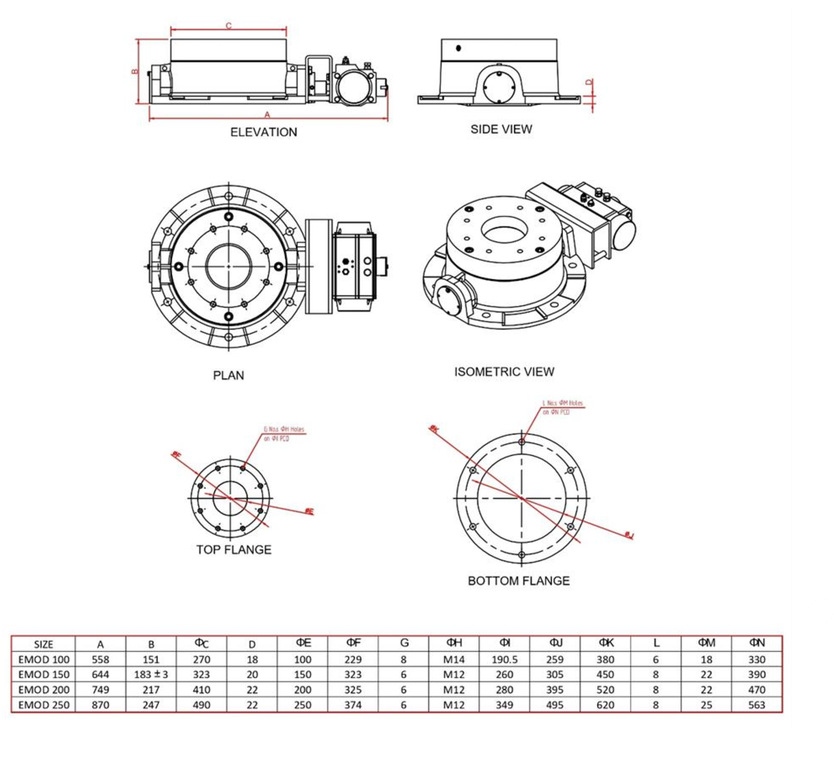

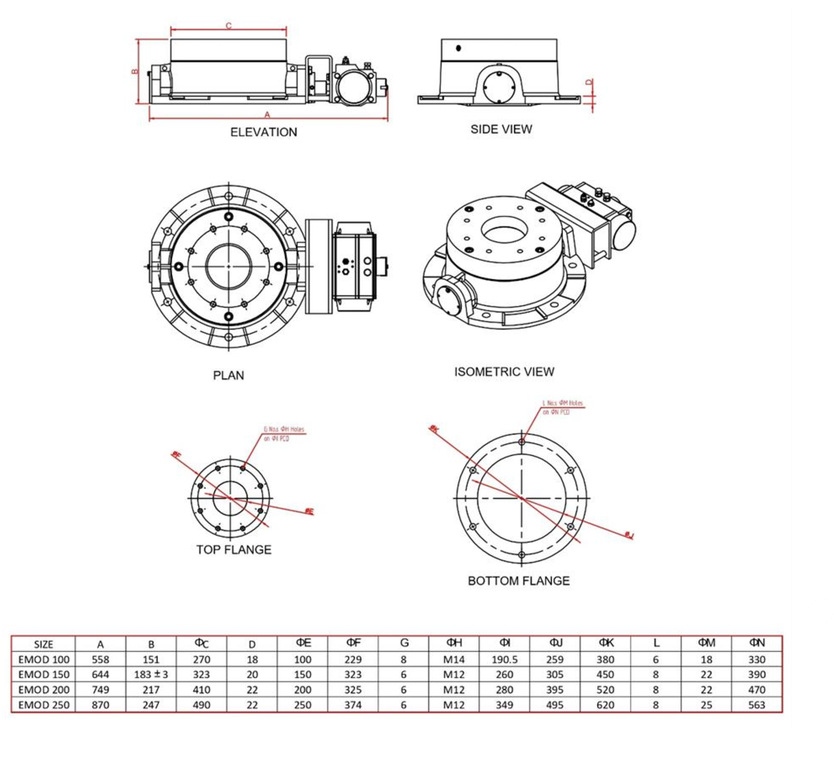

Dimension Chart

Key Components

- Valve Body: A robust, heavy-duty casting (e.g., Cast Iron, Carbon Steel, Stainless Steel) that houses all components and provides flange connections.

-

Dome (Hemisphere): The rotating closing component. This is the primary part in contact with the material during actuation.

- Material: Typically, Stainless Steel or Cast Steel.

- Coatings: This is a key area for customization.

- Chrome Plating: For sticky and abrasive materials.

-

Inflatable Seal: The "heart" of the valve. This is an elastomeric ring that inflates to create the seal.

- Silicone: Food-grade and high-temperature applications.

-

Actuator:

- The valve comes with Actuator direct coupled on shaft or via a flexible coupling.

- Compact rack and pinion actuators units are used to achieve required flap torque.

- Generally, 2.5–5 kg/cm²(g) pressure compressed air pressure is required for actuator operation.

- Control System: A local control box with solenoid valves and proximity switches that ensures the correct "close-then-inflate" and "deflate-then-open" sequence.

Features & Benefits

| Customer Pain Point | RIECO EMOD Valve Feature | Benefit |

|---|---|---|

| Our current valves (butterfly/ball) wear out and leak | Inflatable, Protected Seal | "The EMOD's seal is completely shielded from the material flow. It only inflates to seal after the valve is closed, so it never gets worn down by the abrasive product. This gives it a service life many times longer than a butterfly valve, where the seat is always exposed." |

| We get material blockages and pressure drop | Full, Unobstructed Bore | "When open, the EMOD is 100% full-bore. It's like having an open pipe. This means zero pressure drop, no product degradation, and no ledges or cavities for material to build up and clog the line." |

| We must stop our process to close our valves | Closes Through a Column of Material | "The EMOD is a true process valve. Its dome has a 'wiping' action that can cut through a static or moving column of material. You don't have to stop your feed, which means no loss in production time. It's designed to be used as an inlet/outlet valve on pressure vessels." |

| Our fine powder is leaking and causing a mess/safety hazard | Bubble-Tight, Wear-Compensating Seal | "The inflatable seal provides a perfect, pressure-tight seal every single time, even with fine powders like cement or fly ash. Because it inflates, it automatically compensates for any minor wear, ensuring it seals tightly for thousands of cycles." |

| Our process is high-pressure | Robust, Severe-Service Design | "The EMOD is built for this. Its all-metal dome and body, combined with specialized seals (like Silicon) and coatings (like Hard Chrome), can handle mildly abrasive materials at high pressures where other valves would fail in days." |

Target Applications

Focus your efforts on these high-potential areas:

- Branch Isolation, Diverter Valve, Silo Isolation in pneumatic conveying lines.

- Material Inlet, Material Outlet & Vent / Equalising of pneumatic conveying dense pump

- Handling sticky, gummy, pelletized or granulated substances.

- Highly abrasive flow.

- Sanitary, Food and Pharmaceutical.

- Hopper discharge cut-off.

- Ball, Knife and Butterfly valve replacement.

- Vessel Sealing.

- Inline Flow Isolation.

Dimension Chart

Technical Highlight

- Air cooled design for temperature range up to 150 °C

- Hard chrome surface plating for abrasive material applications

- Rotary Pneumatic actuator

- FG Silicon inflatable seal