In industries such as Cement, Steel, Food, and Pharmaceuticals, "Nuisance Dust" generated at transfer points,

packing stations, and mixers poses a significant environmental and health hazard. Unlike "Process Dust" (where the

powder is the final product), Nuisance Dust is a byproduct that must be captured to comply with pollution control

norms (PCB/CPCB) and ensure a safe workspace.

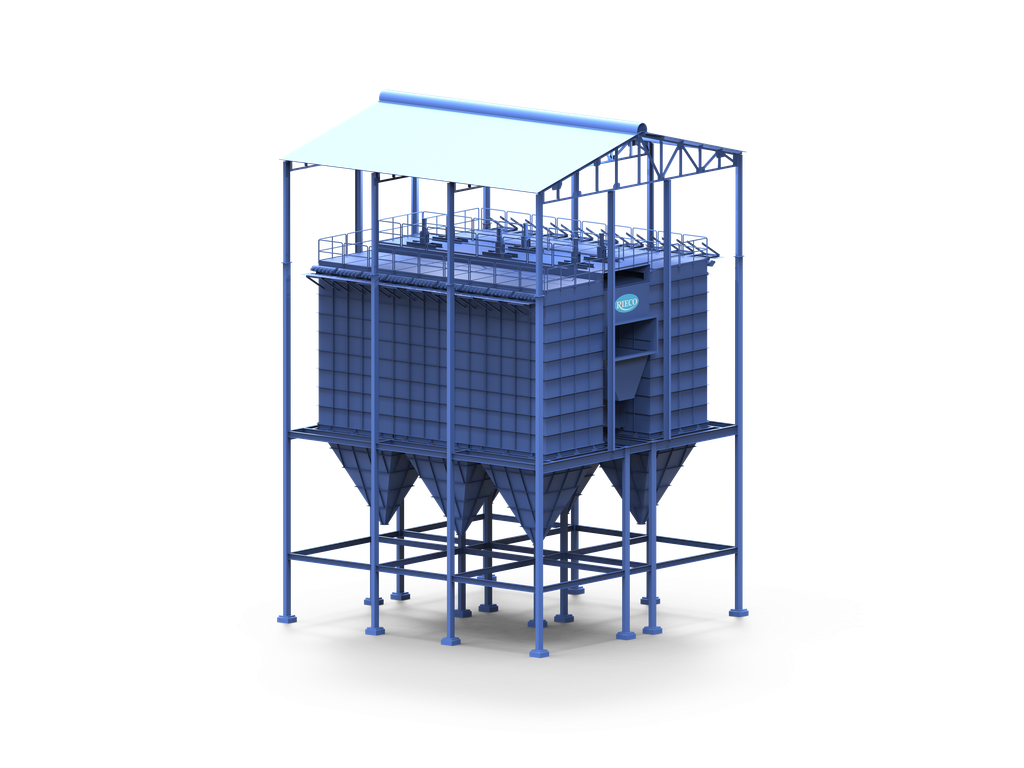

RIECO Industries offers a standardized range of Pulse Jet Bag Filters (M-Series) designed specifically for these

nuisance applications. These systems are engineered to handle light-to-medium dust loads effectively, providing a

clean, emission-free environment with minimal maintenance. This note covers the technical specifications for non

-coal applications ranging from 2,000 m³/hr to 22,000 m³/hr.

Model Characteristics

RIECO offers a standardized "M-Series" range optimized for nuisance venting. The selection depends on the Air-to-Cloth Ratio (ACR), which is typically 1.25 – 1.3 m³/min/m² for general dusts.

| Model | Capacity | Filter Bag Qty | Bag filter Footprint (mm) | Bag filter Height (mm) | Comp. Air Required (m³/hr) |

|---|---|---|---|---|---|

| 20M-12-20TRL | Up to 3000 | 20 | 1320 X 1290 | 7035 | 7.6 |

| 25M-12-20TRL | 3100-3700 | 25 | 1530 X 1290 | 7035 | 9.5 |

| 30M-12-20TRL | 3800-4500 | 35 | 1365 X 1740 | 7430 | 9.5 |

| 36M-12-20TRL | 4500-5400 | 36 | 1575 X 1740 | 7430 | 11.4 |

| 42M-12-20TRL | 5500-6300 | 42 | 1590 X 2030 | 7740 | 11.4 |

| 49M-12-20TRL | 6400-7200 | 49 | 1800 X 2030 | 7740 | 13.3 |

| 56M-12-20TRL | 7400-8200 | 56 | 1800 X 2315 | 8030 | 13.3 |

| 64M-12-20TRL | 8300-9400 | 64 | 2010 X 2315 | 8030 | 15.2 |

| 72M-12-20TRL | 9500-10600 | 72 | 2010 X 2525 | 8317 | 15.2 |

| 81M-12-20TRL | 10700-11900 | 81 | 2220 X 2525 | 8317 | 17.1 |

| 90M-12-20TRL | 12000-13200 | 90 | 2220 X 2735 | 7905 | 17.1 |

| 100M-12-20TRL | 13300-14700 | 100 | 2430 X 2735 | 7905 | 19 |

| 110M-12-20TRL | 14800-16100 | 110 | 2505 X 2945 | 8225 | 19 |

| 121M-12-20TRL | 16200-17800 | 121 | 2715 X 2945 | 8225 | 20.9 |

| 132M-12-20TRL | 17900-19400 | 132 | 2715 X 3155 | 8451 | 20.9 |

| 144M-12-20TRL | 19500-21200 | 144 | 2925 X 3155 | 8451 | 22.8 |

| 156M-12-20TRL | 21300-23000 | 156 | 3010 X 3365 | 8782 | 22.8 |

| 169M-12-20TRL | 23100-24800 | 169 | 3220 X 3365 | 8782 | 24.7 |

| 182M-12-20TRL | 24900-26700 | 182 | 3220 X 3575 | 9350 | 24.7 |

| 196M-12-20TRL | 26800-28800 | 196 | 3430 X 3575 | 9350 | 26.6 |

| 210M-12-20TRL | 28900-30900 | 210 | 3640 X 3575 | 9833 | 28.5 |

| 224M-12-20TRL | 31000-33000 | 224 | 3850 X 3575 | 9833 | 30.4 |

| 238M-12-20TRL | 33100-35000 | 238 | 4060 X 3575 | 10110 | 32.3 |

| 252M-12-20TRL | 35100-37000 | 252 | 4345 X 3575 | 10640 | 34.2 |

| 266M-12-20TRL | 37100-39100 | 266 | 4555 X 3575 | 10640 | 36.1 |

* Capacities based on ACR of 1.3 m/min. Values vary based on dust density and temperature.

Design and Operating Principle

The system operates on a continuous, automated filtration principle designed for 24/7 operation.

- Step 1: Dust Aspiration: Dust-laden air is drawn from the source (e.g., belt conveyor transfer point, elevator boot, or dump station) through a duct network into the Bag Filter.

- Step 2: Filtration: The air enters the dirty air plenum and hits a baffle plate, causing heavier particles to drop into the hopper. The fine dust travels upward and is trapped on the outer surface of the filter bags (typically Polyester Needle Felt). Clean air passes through the bag, into the clean air plenum, and exits via the ID Fan .

- Step 3: Pulse Jet Cleaning: As dust builds up, the differential pressure rises. A sequential controller activates Solenoid Valves (40mm / 1.5") to release short bursts of compressed air into the bag cages. This "pulse" expands the bag, dislodging the dust cake, which falls into the hopper.

- Step 4: Discharge: The collected dust is continuously evacuated from the hopper via a Rotary Airlock Valve (RAL) to prevent air leakage.

Key Components

- Filter Bags: High-efficiency non-woven Polyester Needle Felt (500 GSM) is standard. Treatments like Oil & Water Repellent (OWR) or Anti-Static are used for specific applications like Food or Polymers.

- Cages: Rigid support frames (Mild Steel or SS304) with venturi tubes to maximize the pulse cleaning energy.

- Solenoid Valves: High-response diaphragm valves (Size: 1.5” / 40mm) ensure powerful cleaning with minimal air consumption.

- Rotary Airlock (RAL): Precision-machined valve (Models RAL-200 to RAL-250) ensures a positive air seal at the discharge.

- ID Fan: Centrifugal fan sized to overcome the system resistance (typically 150–200 mmWC).

Key Features & Benefits

- Environmental Compliance: Designed to achieve outlet emission levels < 20 mg/Nm³, meeting stringent pollution control norms

- Online Cleaning: The Pulse Jet system cleans rows of bags sequentially while the unit is running, ensuring no downtime.

- Standardized Design: Pre-engineered "TRL" (Top Removal) designs allow for quick delivery and easy spare parts availability.

- Safety Options: For combustible dusts (St1/St2 class in Food/Pharma), units can be equipped with Explosion Vents and Anti-Static bags.

Automation & Integration

The system is controlled by a Sequential Timer Board:

- Time-Based Cleaning: Pulses are triggered at fixed time intervals (e.g., every 10 seconds)

- Demand-Based (Delta-P): An optional Differential Pressure Switch triggers cleaning only when the filter resistance reaches a set point (e.g., 120 mmWC), saving compressed air

- Safety Interlocks: Zero Speed Switch (ZSS) on the Rotary Valve to detect blockage

Applications

Based on the recommended Air-to-Cloth Ratios (ACR):

- Cement & Minerals (ACR 1.25): Clinker transfer points, Packer venting, Fly ash silo venting.

- Steel & Metals (ACR 1.25): Sinter plant de-dusting, Flux handling, SMS additives.

- Food & Agriculture (ACR 1.25): Grain receiving pits, Flour silo venting, Sugar dust collection (with dehumidification).

- Chemicals & Fertilizers: Urea bagging, Detergent powder handling, Bentonite processing.

- Pharmaceuticals: Tablet press venting, granulation dust (Requires SS construction).

Model Characteristics

RIECO offers a standardized "M-Series" range optimized for nuisance venting. The selection depends on the Air-to-Cloth Ratio (ACR), which is typically 1.25 – 1.3 m³/min/m² for general dusts.

| Model | Capacity | Filter Bag Qty | Bag filter Footprint (mm) | Bag filter Height (mm) | Comp. Air Required (m³/hr) |

|---|---|---|---|---|---|

| 20M-12-20TRL | Up to 3000 | 20 | 1320 X 1290 | 7035 | 7.6 |

| 25M-12-20TRL | 3100-3700 | 25 | 1530 X 1290 | 7035 | 9.5 |

| 30M-12-20TRL | 3800-4500 | 35 | 1365 X 1740 | 7430 | 9.5 |

| 36M-12-20TRL | 4500-5400 | 36 | 1575 X 1740 | 7430 | 11.4 |

| 42M-12-20TRL | 5500-6300 | 42 | 1590 X 2030 | 7740 | 11.4 |

| 49M-12-20TRL | 6400-7200 | 49 | 1800 X 2030 | 7740 | 13.3 |

| 56M-12-20TRL | 7400-8200 | 56 | 1800 X 2315 | 8030 | 13.3 |

| 64M-12-20TRL | 8300-9400 | 64 | 2010 X 2315 | 8030 | 15.2 |

| 72M-12-20TRL | 9500-10600 | 72 | 2010 X 2525 | 8317 | 15.2 |

| 81M-12-20TRL | 10700-11900 | 81 | 2220 X 2525 | 8317 | 17.1 |

| 90M-12-20TRL | 12000-13200 | 90 | 2220 X 2735 | 7905 | 17.1 |

| 100M-12-20TRL | 13300-14700 | 100 | 2430 X 2735 | 7905 | 19 |

| 110M-12-20TRL | 14800-16100 | 110 | 2505 X 2945 | 8225 | 19 |

| 121M-12-20TRL | 16200-17800 | 121 | 2715 X 2945 | 8225 | 20.9 |

| 132M-12-20TRL | 17900-19400 | 132 | 2715 X 3155 | 8451 | 20.9 |

| 144M-12-20TRL | 19500-21200 | 144 | 2925 X 3155 | 8451 | 22.8 |

| 156M-12-20TRL | 21300-23000 | 156 | 3010 X 3365 | 8782 | 22.8 |

| 169M-12-20TRL | 23100-24800 | 169 | 3220 X 3365 | 8782 | 24.7 |

| 182M-12-20TRL | 24900-26700 | 182 | 3220 X 3575 | 9350 | 24.7 |

| 196M-12-20TRL | 26800-28800 | 196 | 3430 X 3575 | 9350 | 26.6 |

| 210M-12-20TRL | 28900-30900 | 210 | 3640 X 3575 | 9833 | 28.5 |

| 224M-12-20TRL | 31000-33000 | 224 | 3850 X 3575 | 9833 | 30.4 |

| 238M-12-20TRL | 33100-35000 | 238 | 4060 X 3575 | 10110 | 32.3 |

| 252M-12-20TRL | 35100-37000 | 252 | 4345 X 3575 | 10640 | 34.2 |

| 266M-12-20TRL | 37100-39100 | 266 | 4555 X 3575 | 10640 | 36.1 |

* Capacities based on ACR of 1.3 m/min. Values vary based on dust density and temperature.

Performance Parameters

- Air-to-Cloth Ratio (ACR): 1.25 to 1.5 m³/min/m² (Dependent on dust characteristics)

- Pressure Drop: 100 – 150 mmWC across the filter

- Temperature: Standard: Ambient to 130°C (Polyester). High Temp: Up to 250°C (Nomex/Fiberglass)

- Cleaning Air Pressure: 5 – 6 Bar (g) dry, oil-free air